The global shift to electric vehicles has intensified the demand for advanced battery technology. The International Energy Agency predicts that by 2025, the global sales of electric vehicles will reach 20 million units. The core of this change lies in the demand for safer and more efficient battery production. Nowadays, the breakthrough innovation in the field of square battery welding is meeting this challenge.

Global Technological Progress and Regional Competition

Asia: China and Japanese precision manufacturing pioneers

China battery giants Contemporary Amperex Technology Co., Limited(CATL) and BYD have redefined the manufacturing standard by integrating a zero thermal damage laser welding system. According to CATL’s 2025 interim report, adopting these systems has increased battery yield by 15% and reduced the risk of thermal runaway by 30%. A factory in Dongguan further demonstrates that welding efficiency has improved by 20% and unit costs have been reduced by 8%, highlighting the technology’s scalability. In Japan, the joint venture between Toyota and Panasonic used the innovative technology of solid-state battery welding, which reduced the thermal stress damage by 90% and enabled the battery to last for more than 3,000 charging cycles, which is the benchmark for the long life of the industry.

(Credit: pixabay lmages)

Europe: German automakers accelerate green transformation

According to the data of German automobile industry, BMW i7 battery pack is produced using ultra-precision laser welding machine, reducing energy consumption by 40% and carbon emission by 25%. At the same time, the Swedish company Northvolt demonstrated how zero thermal damage welding technology can realize a faster and more reliable assembly line, and won an order of 20 billion euros from Volkswagen.

North America: Tesla and QuantumScape redefine infinite possibilities

Tesla resolved the production bottleneck of 4680 battery cells by optimizing the laser welding protocol, and reduced the defect rate from 5% to 0.5% in the second quarter of 2025. The cooperation between QuantumScape and solid-state battery developers has improved the fast charging ability by 40% and raised the thermal runaway threshold to 400°C, setting a new safety standard.

Industry influence and supply chain evolution

BloombergNEF predicts that by 2030, zero thermal damage welding technology will reduce global battery production cost by 12% and push the market scale to 1.2 trillion US dollars. EU battery regulations require that the thermal damage limit of batteries should be lower than 0.1 J/cm by 2030, which will accelerating the popularization of batteries. The cooperation between LG Energy Solution and General Motors is a good example. Its welding technology upgrade will increase the production capacity of Ultium platform from 30 GWh to 50 GWh.

Challenges and future prospects

Although the technology has bright prospects, it also faces many challenges. The high initial cost ($50 million per production line) is still unbearable for small manufacturers.

However, the consensus is obvious. This is the most important progress since the winding technology of prismatic battery. The materials scientists at MIT emphasized its potential of “redefining the manufacturing paradigm”, while Goldman Sachs predicted that by 2026, the market size of laser welding system will reach 8 billion US dollars, among which China enterprises such as Styler Electronic will occupy 40% of the market share.

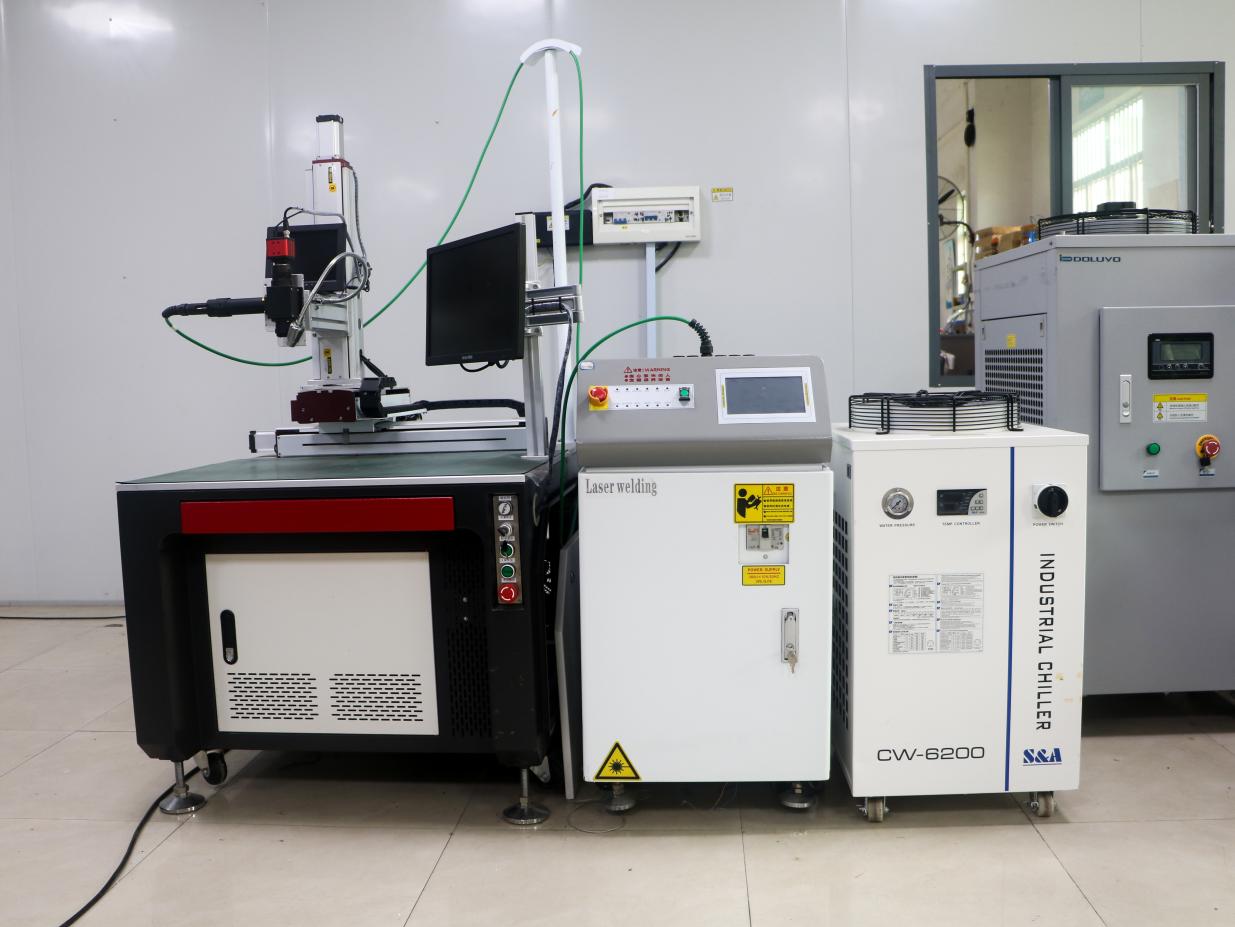

Significance of laser welding machine

The laser system provides unparalleled accuracy, which can control the weld size in micron level and ensure the uniformity of prismatic battery. Different from traditional methods, they eliminate thermal deformation, which is very important for high-density battery packs. With the surge in demand for electric vehicles, manufacturers are increasingly relying on these machines to meet safety and efficiency goals.

Styler Electronic (Shenzhen) Co., Ltd: Leading the Welding Revolution

Styler Electronic focuses on innovation, developing cutting-edge battery laser welding machine(https://www.stylerwelding.com/6000w-automatic-laser-welding-machine-product/) and battery welding(https://www.stylerwelding.com/solution/energy-storage-system/) solution tailored for prismatic battery production. Our system combines the characteristics of accuracy, speed and zero thermal damage to support global manufacturers.

Precision welding improves your production efficiency.

The battery laser welding machine designed by Styler Electronic (Shenzhen) Co., Ltd has both zero thermal damage accuracy and industry-leading reliability. Our battery welding solutions ensure that:

l Adaptive laser control: Real-time temperature adjustment to realize defect-free welding.

l Scalable automation: Seamless integration into existing production lines.

Explore how our laser machine can transform your battery production. Contact us now to get customized solutions and join the forefront of the electric vehicle revolution.

(the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site. UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

Post time: Sep-02-2025