In the rapidly evolving world of battery manufacturing—powering everything from EVs to consumer electronics and grid storage—welding stands as a critical, yet often challenging, process for battery pack assembly. The integrity of every connection directly impacts the pack’s safety, performance, and longevity. At STYLER, we specialize in advanced welding and assembly solutions for pack-level integration, including precision Resistance Spot Welders, high-speed Laser Welding Machines, and turnkey Battery Module & Pack Assembly Lines.

We’ve compiled the ten most frequent questions our engineering team encounters regarding battery pack welding, providing expert insights to help you navigate its complexities.

1. What is the most suitable welding process for connecting cylindrical cell modules or battery pack busbars?

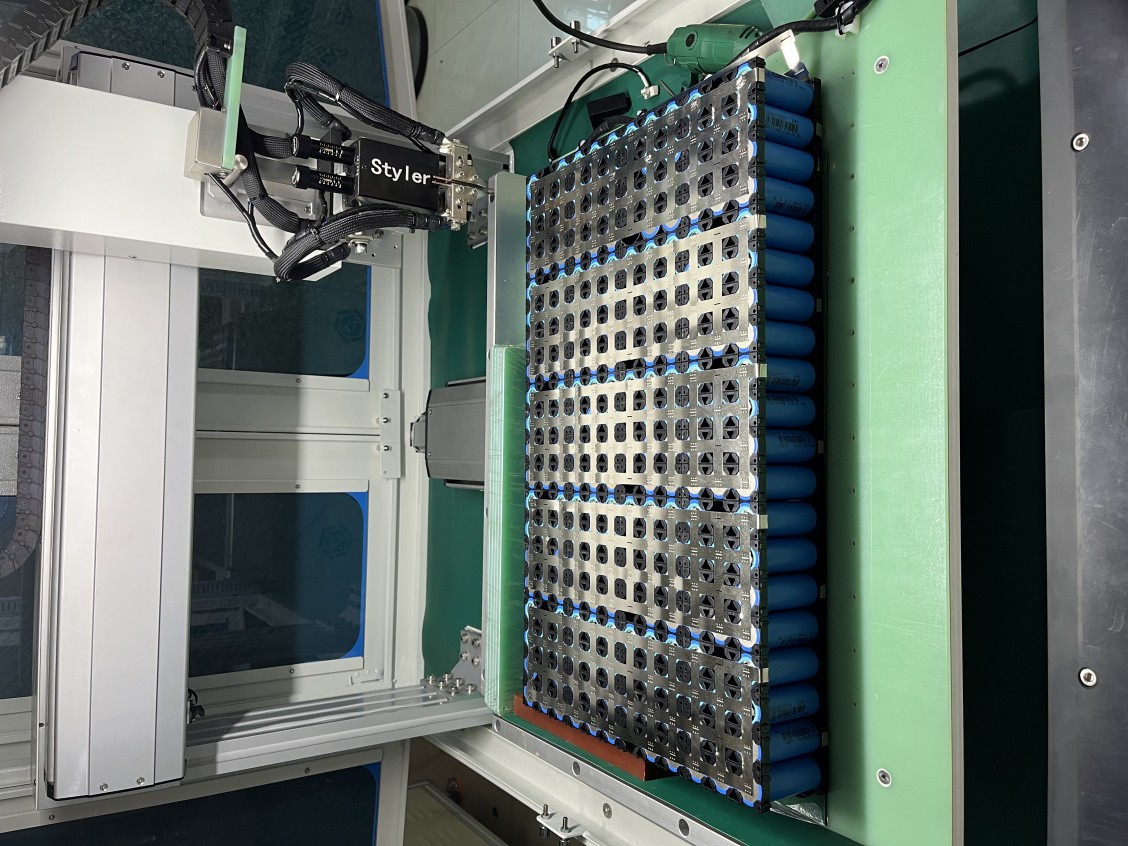

For interconnecting cells into modules or joining busbars within a pack, Resistance Spot Welding is often a preferred choice. It’s a fast, cost-effective, and reliable method for creating multiple strong electrical connections. STYLER’s spot welders, utilizing advanced transistor technology, deliver exceptional speed and stability, with constant current feedback and adaptive control to handle thin, sensitive materials like nickel-plated busbar.

2. How do we prevent overheating and thermal damage to battery cells during pack welding?

Thermal management during pack assembly is paramount. The key is controlling energy input with extreme precision at the connection points. Our Transistor-based Resistance Spot Welders achieve this through ultra-short, precisely timed welding cycles (milliseconds), minimizing heat spread. For laser welding, selecting the correct parameters and using high-speed galvanometer scanners localizes heat input. Our systems can integrate thermal monitoring to ensure nearby cells remain within safe limits.

3. Aluminum and copper-aluminum composites are common in pack busbars. What are the welding solutions?

Welding these materials requires careful process selection. For spot welding, pure nickel’s high conductivity demands high current in a very short time. STYLER’s transistor welders deliver the necessary rapid, stable energy pulse. For laser welding of aluminum busbars and connections, it is highly effective. However, for purely copper busbars in pack assembly, laser welding presents challenges due to high reflectivity and thermal conductivity. A practical and recommended alternative is to use copper-aluminum composite busbars (clad materials), where the laser weld is performed on the aluminum layer, ensuring a reliable and more stable joint.

4. How critical is material cleanliness and surface preparation for pack welding?

Extremely critical. Oxides, oils, and contaminants on busbars or terminals cause inconsistent weld quality, increased electrical resistance, and potential failure. A robust pack assembly process should include proper cleaning (e.g., laser cleaning, plasma cleaning) immediately before welding. STYLER’s Battery Pack Assembly Lines can integrate automated cleaning stations to ensure consistent surface conditions for every connection.

5. How do we ensure consistent weld quality in high-volume pack production?

Consistency comes from equipment stability, process monitoring, and automation. Our machines feature:

Real-time Process Monitoring: Measuring dynamic resistance (spot welding) for every weld.

Closed-Loop Adaptive Control: Automatically adjusting parameters based on feedback.

100% Post-Weld Inspection: Integrating vision systems for weld placement and electrical resistance testing into the assembly line for quality assurance.

6. What are the key advantages of laser welding in battery pack assembly?

Laser Welding offers exceptional flexibility in weld geometry (lines, circles, contours), minimal mechanical stress, and the ability to weld in confined spaces within a pack structure. It is ideal for welding module end plates, cover seams (where applicable), and complex busbar shapes. It reduces tooling wear and enables high-speed, aesthetically clean seams.

7. When is a turnkey Battery Pack Assembly Line necessary vs. standalone welders?

Standalone welders are perfect for R&D, pilot lines, or specific sub-assembly steps. A turnkey Battery Pack Assembly Line is essential for integrated, high-volume production of complete modules or packs. STYLER designs lines that automate the entire sequence: module stacking, busbar placement, welding (spot or laser), electrical testing, and final integration. This maximizes throughput, minimizes human error, ensures traceability, and optimizes floor space.

8. How do you address weld spatter in a battery pack, which can cause short circuits?

Spatter inside a pack is a serious safety hazard. In spot welding, it’s controlled by optimizing the weld pulse shape and electrode force. Our Transistor-based Spot Welders provide superior pulse control, significantly reducing spatter generation. In laser welding, spatter is minimized by using correct shielding gas, optimal focal position, and tailored parameters. STYLER’s systems are configured to produce clean, spatter-minimized welds critical for pack safety.

9. What metrics should we use to validate weld quality in a pack?

Beyond visual inspection, key validation metrics include:

Electrical Resistance/Conductivity: Measured across each weld joint; low and consistent resistance is critical for pack performance.

Pull/Peel Strength: Mechanical destructive testing on samples to ensure connection integrity meets specifications.

Nugget Size/Seam Penetration: Verified via cross-section analysis during process qualification.

Process Data Logging: Every weld’s parameters (current, time, energy) are recorded by STYLER equipment for full production traceability.

10. How is the industry adapting welding for new pack designs like CTC (Cell-to-Chassis) or large structural packs?

These designs demand welding processes that create robust, reliable electrical and sometimes structural connections on a larger scale. They push requirements for weld depth, speed, and consistency. High-Power Laser Welders are increasingly used for long seam welds on pack enclosures and structural busbars. STYLER is at the forefront, developing solutions with the necessary power, precision, and agility to meet these next-generation pack assembly challenges.

Conclusion

Battery pack welding is a precise discipline focused on creating perfect electrical connections within a safe and reliable assembly. The right partnership and technology choice are decisive for your product’s success.

At STYLER, we provide targeted solutions for battery pack integration. From the high-speed stability of our Transistor-based Resistance Spot Welders and the flexible precision of our Laser Welding Systems to the fully integrated automation of our Battery Pack Assembly Lines, we are committed to empowering your manufacturing with reliability, innovation, and excellence.

Ready to optimize your battery pack welding process? Contact the STYLER expert team today for a consultation.

Post time: Dec-11-2025