Launching a startup in the battery industry comes with unique challenges, especially when transitioning from prototype to full-scale production. One of the most critical aspects of battery manufacturing is ensuring precise, reliable, and scalable welding solutions(https://www.stylerwelding.com/solution/electric-vehicle/) for battery pack assembly. Whether you’re developing electric vehicle (EV) batteries, energy storage systems, or portable power solutions, the right welding technology can make or break your production efficiency.

The Welding Challenge in Battery Production

Battery packs require high-precision welding to maintain electrical conductivity, structural integrity, and thermal management. Poor welding can lead to increased resistance, overheating, or even catastrophic failure. Startups often struggle with:

- Inconsistent weld quality due to manual processes

- Low throughput when scaling from prototype to mass production

- High costs from trial-and-error adjustments

To overcome these hurdles, you need a welding solution that adapts to your specific battery design while ensuring repeatability and speed.

Custom Welding Solutions for Every Stage

At Styler, we specialize in tailored welding and assembly solutions for battery pack manufacturing. Whether you’re at the prototyping phase or ready for high-volume production, our expertise in laser welding, ultrasonic welding, and resistance welding ensures optimal performance for your battery cells and modules.

Why Choose Styler for Your Battery Welding Needs?

✅ Customized Solutions – We design welding systems based on your battery chemistry, pack geometry, and production volume.

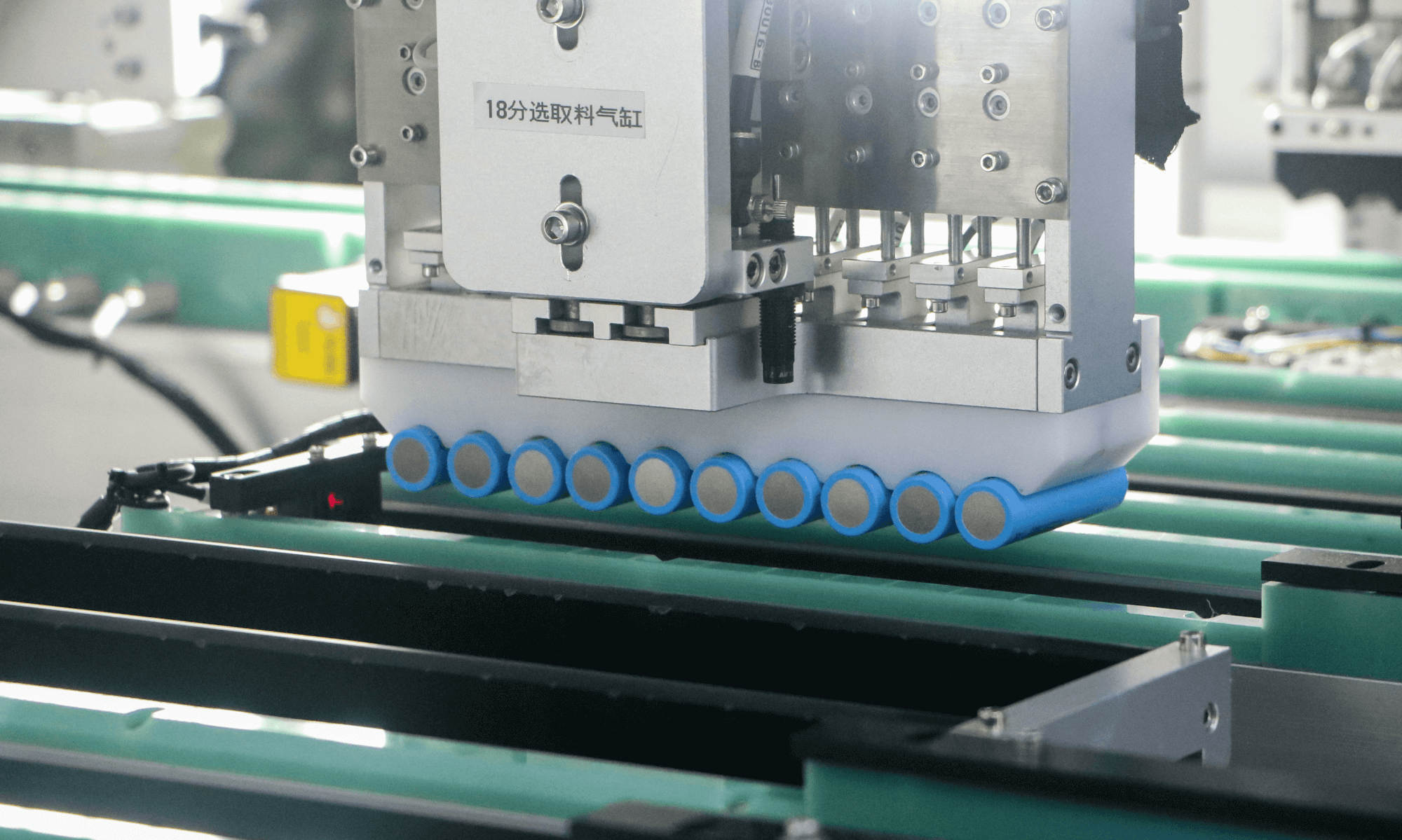

✅ High Precision & Speed – Automated welding processes reduce defects and increase throughput.

✅ Scalable Production – From small batches to mass production, our solutions grow with your business.

✅ Cost Efficiency – Minimize waste and rework with optimized welding parameters.

From Prototype to Full-Scale Production

Many startups begin with manual welding for prototypes but quickly hit bottlenecks when ramping up. Styler bridges this gap by offering:

- Prototype Development Support – Test different welding methods to find the best fit.

- Semi-Automated Systems – For mid-volume production with controlled quality.

- Fully Automated Lines – High-speed, robotic welding for mass production.

Need a reliable welding solution for your battery pack assembly? Let Styler design a custom welding system tailored to your startup’s needs.

Contact us today to discuss how we can help you scale efficiently—from prototype to mass production!

#BatteryManufacturing #WeldingSolutions #EVStartups #EnergyStorage #StylerWelding

The information provided by Styler on https://www.stylerwelding.com/ is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site. UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

Post time: Jul-23-2025