Along with the booming market of electric vertical takeoff and landing aircraft (eVTOL) and advanced unmanned aerial vehicles, lightweight aviation has changed from ideal to reality. The precision spot welding technology will be deeply discussed in this paper, which benefits from the innovation of battery welding equipment and how to redefine aerospace connection. Meanwhile, it meets the standards of National Aeronautics and Space Administration (NAS), Military Aviation (MIL) and Aviation Management System (AMS). Discover how the world’s leading companies use this technology to achieve unparalleled security and consistency.

(Credit: pixabay lmages)

The modern aviation needs high-strength aluminum alloy, titanium alloy and carbon fiber composite materials with the best strength-to-weight ratio. The traditional welding method has the risk of thin-wall deformation or material deterioration, which can not meet the strict aviation standards. As the times require, precision spot welding technology comes into being: local heating, rapid cooling and automation make it an ideal choice for skin panels, frames and battery compartments.

Application of battery welding in aviation welding technology

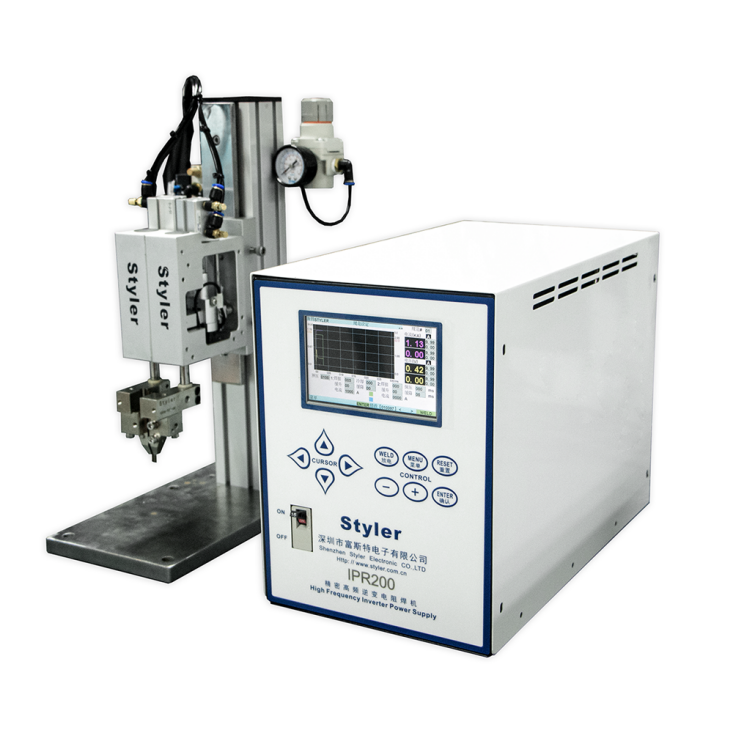

With Styler Electronic’s professional technology in the field of battery welding, it can achieve zero damage to battery connection, no gap weld and ultra-low resistance. It perfectly meets the requirements of aerospace for structural integrity and thermal management. For example, a North American eVTOL manufacturer encountered dissimilar metal connection problems when welding thin aluminum plates to copper buses. They use transistor inverter DC spot welding machine. The equipment realizes the precise welding of aluminum and copper materials through precise DC control, with almost no splash and stable weld quality. Welding joints not only have excellent electrical conductivity, but also pass the rigorous vibration test with a margin of 30% exceeding the standard, which provides a guarantee for aviation reliability.

The “Tiangong” series embodies aviation ideas:

Digital accuracy: All-digital transistor inverter programs the current waveform, and its heat input control accuracy is 10 times higher than that of AC system, making it an ideal choice for sensitive alloys such as 3003 aluminum alloy or Inconel.

Internal quality assurance: real-time monitoring (current, voltage, dynamic resistance) generates a “digital birth certificate” for each welding, which seamlessly supports the traceability requirements of AS9100.

General use of materials: professional parameter library and self-learning AI can adapt to any combination of aerospace materials, from thin plates to thick composite materials.

Why did you choose to cooperate with Styler Electronic?

Choosing a welding machine supplier is not only to buy a machine, but also to work with a team that understands aerospace compliance. We provide one-stop solutions from advanced welding equipment to complete process support. As a professional supplier of battery welding equipment, we not only provide equipment, but also provide full-process services such as process development, parameter optimization and personnel training to help customers quickly establish stable and efficient production capacity.

With the increasing popularity of urban air traffic, the demand for efficient and reliable manufacturing has also exploded. Precision spot welding has become a mature and developing technology and will also play a key role. Styler Electronic provides a tool to help you take off for manufacturers who are looking for precision, compliance and innovation.

Contact Styler Electronic (Shenzhen) Co., Ltd. to learn how our battery welding equipment and spot welding solutions can help your production transformation and upgrading. Explore the precision welding redefined by aviation experts for the aviation field.

(the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site.

Post time: Dec-03-2025