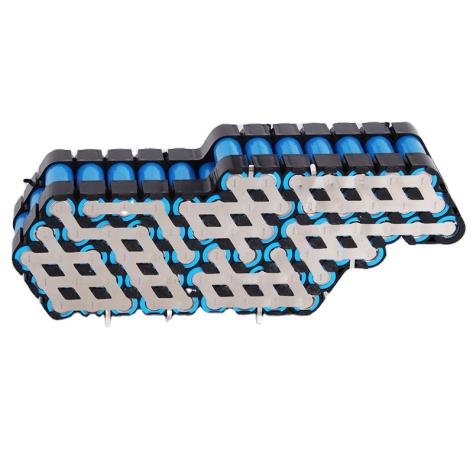

In lithium-ion battery pack manufacturing, welding performance directly impacts the conductivity, safety, and consistency of the subsequent battery pack. Resistance spot welding and laser welding, as mainstream processes, each have distinct characteristics, making them suitable for different battery materials and structural stages.

Resistance spot welding: The preferred method for welding nickel sheets

Resistance spot welding utilizes the resistance heat generated by current passing through nickel sheets to create a strong metallurgical bond. This concentrated heat and rapid welding process make it ideal for welding materials such as pure nickel or nickel ribbon, commonly used in lithium-ion batteries. Its advantages lie in its cost-effectiveness and mature process, making it a reliable choice for high-volume welding of battery cell tabs and connectors.

(Credit: styler Images)

(Credit: styler Images)

Laser welding: A precision method for welding aluminum and thicker materials

When welding aluminum casings, aluminum connectors, or thicker structural components, laser welding demonstrates its unique advantages. The laser beam’s extremely high energy density allows it to handle relatively thick aluminum busbar, achieving deep penetration welds and producing aesthetically pleasing, airtight welds. It is ideal for precision joining aluminum components in battery modules and packs.

(Credit: styler Images)

Full-process production line design from cell to pack

A complete lithium battery production line typically integrates multiple processes. Based on your specific material (nickel/aluminum/copper) and battery pack structure, we can integrate steps such as cell sorting and busbar welding, from individual cells to complete battery packs, to create customized and flexible production solutions that balance efficiency, cost, and performance.

In battery manufacturing, there’s no one-size-fits-all welding solution. Different battery types often require specific welding processes. We understand this and are committed to providing a wide range of advanced welding equipment to help you find the best option. At Styler, we provide more than just equipment; we offer a process path tailored to your needs. Talk to us and let us use the most appropriate welding technology to protect your battery.

Want to upgrade your technology? Let’s talk. Visiting our website http://www.styler.com.cn , just email us sales2@styler.com.cn and contact via +86 15975229945.

Post time: Oct-15-2025