In the race to meet soaring global demand for electric vehicles and energy storage, battery manufacturers face a critical challenge: scaling production without compromising on quality, safety, or flexibility. The heart of this scaling effort lies in the assembly process, particularly the precise and reliable welding of cylindrical cells into modules and packs. A bottleneck here can stall an entire line. The solution is emerging not from simply faster machines, but from smarter, more adaptable systems: the Modular Welding Workstation.

This article explores how modern, modular workstation design is revolutionizing high-speed cylindrical cell production, becoming the indispensable engine for efficient, future-proof battery manufacturing.

The Limits of Fixed, Linear Lines

Traditional, fixed automation lines for cell welding are built for a single product. They are excellent for high-volume, low-mix scenarios. However, the battery industry is dynamic. Cell formats (21700, 46120, etc.), module designs, and weld configurations (series, parallel, matrix) evolve rapidly. A rigid production line cannot adapt. Retrofitting or re-tooling is costly, causes massive downtime, and halts production. This inflexibility is a significant risk in a fast-paced market.

The Modular Advantage: Agility as Standard

A modular welding workstation flips this paradigm. Instead of one long, fixed line, production is broken down into self-contained, functional units—or modules. Each module, such as a cell stacking station, a busbar placement station, or crucially, a precision welding station, is an independent island of automation.

The power of this design lies in its core principles:

1. Plug-and-Play Scalability: Need higher throughput? Integrate additional, identical welding modules to work in parallel. Production can be scaled up or reconfigured with minimal disruption, much like adding high-performance computing nodes to a server cluster.

2. Unmatched Flexibility: When a new cell format or module design is introduced, only the specific modules requiring change—like end-effector tooling or fixtures—need updating. The core infrastructure, including motion systems and control architecture, remains intact. This drastically reduces changeover time and cost.

3. Enhanced Uptime and Maintenance: If one welding module requires maintenance, it can be isolated and serviced while others continue to operate. This parallel processing architecture eliminates single points of failure, maximizing overall equipment effectiveness (OEE).

The Heart of the Module: Precision Welding Technology

At the core of each welding module is the technology that creates the permanent, low-resistance electrical and mechanical bonds. This is where reliability is non-negotiable. Advanced systems integrate high-precision laser welders or sophisticated resistance spot welders to meet this demand.

For example, incorporating a Styler precision spot welder into a modular workstation brings distinct advantages for cylindrical cell assembly. Its stable energy output and advanced force control are critical for welding the thin, often dissimilar materials of cell tabs and nickel-plated steel busbars. Consistent weld nugget formation without spatter or thermal damage to the sensitive cell is paramount for safety and longevity. When such a welder is embedded within a modular, servo-driven motion system, it becomes a unit capable of executing complex weld patterns across a cell matrix with speed and repeatability.

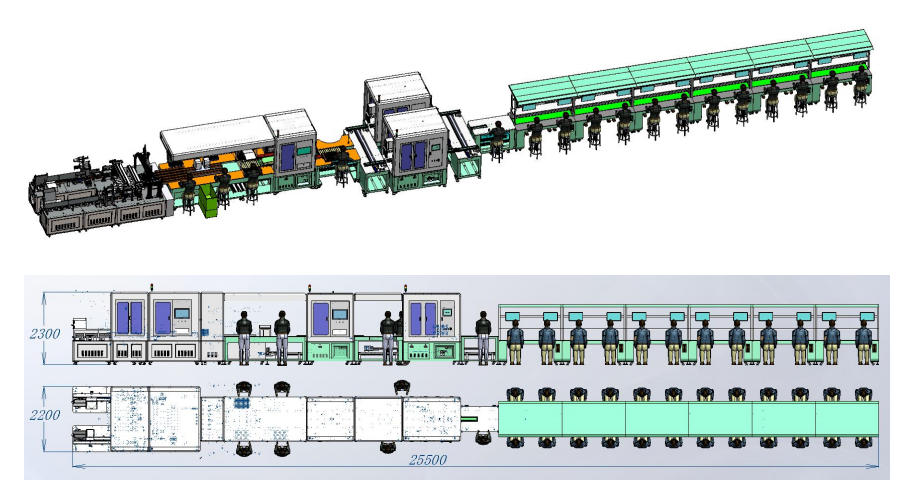

From Workstation to Semi-Automated Line: The Optimal Hybrid

The modular concept extends brilliantly to creating semi-automated assembly lines. Here, manual operations for tasks like visual inspection, connector assembly, or harness routing are ergonomically integrated with automated modules.

Consider a semi-automatic busbar welding line built on modular principles. An operator might load a pre-stacked cell fixture onto a pallet. The pallet then flows to an automated station equipped with a Styler welder, which performs all busbar-to-tab welds with flawless consistency. The pallet proceeds to a manual station for thermal interface material application or voltage tap inspection, before moving to the next automated module. This hybrid approach balances the flexibility and judgment of human workers with the speed, precision, and consistency of automation where it matters most—at the weld joint.

Conclusion: Building for the Future, Today

For battery manufacturers, investing in a modular welding workstation design is an investment in resilience and growth. It transforms the production floor from a static, fragile chain into a dynamic, reconfigurable network. By integrating core precision technologies like advanced spot welders into this flexible architecture, companies can achieve the holy grail of modern manufacturing: high-speed output, unwavering quality, and the agility to adapt to tomorrow’s requirements.

This modular engine doesn’t just power today’s production lines; it fuels the innovation of the batteries of the future.

The information provided by Styler on https://www.stylerwelding.com/ is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site. UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

Post time: Dec-31-2025