Along with the rapid development of 5G, AIOT and new energy technologies, household appliances are experiencing a wave of innovation like never before. Under this background, Asiatic spot welding technology, with its high precision, incomparable efficiency and outstanding reliability, has already become an indispensable key process in the manufacturing of household appliances all over the world.

Breakthrough: How does spot welding change the rules of the game?

✔Micron precision welding: ultra-fine parts that can be processed up to at least 0.1mm, meeting the requirements of precision equipment, e.g. folding mobile phone screen and wireless headphone

✔Automatic adaptive intelligent control: Artificial intelligence adjusts welding variables in real time, improving the product rate to above 99.9%

✔Ultra-high-speed production: the welding speed of one machine exceeds 3000 points per minute, supporting the production of billions of smart wearable devices

✔Green manufacturing: compared with traditional laser welding, 50% energy consumption, reduced carbon emission, contribute to sustainable development.

Asia spot welding Industry Ecosystem: World leading?

*China: has the largest spot welding equipment production base and the market share reaches 75%. Famous companies such as Nyeongdeok Era and Villadi are applying sting welding equipment extensively.?

*Japan – By benchmarking precision welding technology, it will provide nano-level welding solutions to high-tech products such as Apple and SONY.

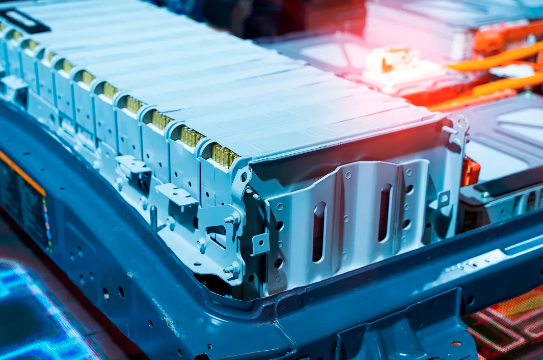

*Korea: Lead in battery welding. The welding efficiency of a single machine is 2500 circuits per minute, driving the revolution of electric cars. Southeast Asia is an emerging manufacturing center, the annual growth rate of spot welding automation investment reaches 40%, has already become a key part of the global supply chain.

Market Trend: The future has already arrived

It is predicted that by 2025, the spot welding equipment market will exceed us $12 billion, of which Asia will account for more than 65%.

It is expected that purchase of related facilities will increase by 300% in 2026 due to huge increase in demands for welding of batteries that are new energy.

The miniaturization and flexibility of the former have promoted the iterative development of ultra-precision welding technology.

What makes spot welding so important?

The spot welding technology directly determines the performance, safety, and life span of products from fine sensors in smartphones to batteries in electric vehicles. Asian companies are redefining global manufacturing standards through continuous innovation!

From:https://www.fortunebusinessinsights.com

# Smart manufacturing # consumer # New Energy # Industry 4.0 # Made in Asia

Post time: Jun-21-2025