28 July 2025 – in a context of accelerated global transformation towards low carbon, Australia is promoting sustainable production through innovative welding technologies, with spot welding technology playing a key role in reducing carbon emissions and improving energy efficiency.

With the support of government policies and the upgrading of business technologies, the Australian manufacturing industry is moving towards a greener and more efficient environment. Environmental advantages of spot welding technology spot welding is a highly efficient resistance welding process, widely used in the automotive, building and metallurgy industries. Compared to traditional welding methods, spot welding has advantages such as low energy consumption, less material waste and no harmful gas emission.

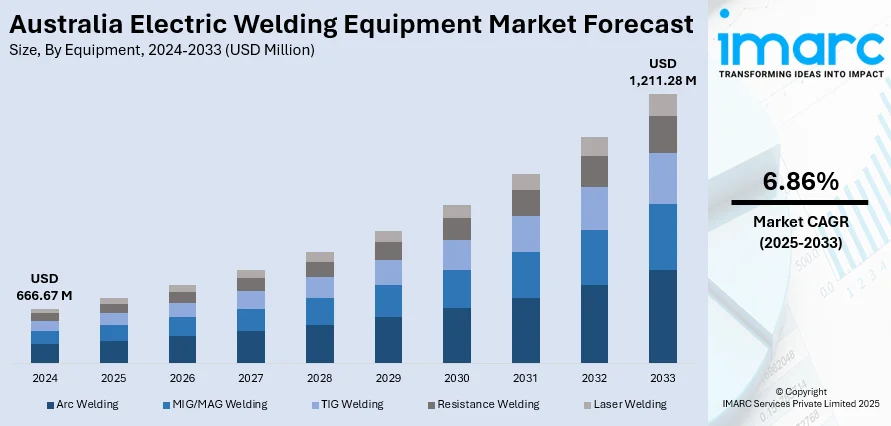

According to the latest industry report, the Australian spot welding equipment market is expected to grow at an average annual growth rate of 6.86% between 2025 and 2033, with the adoption of automation and energy-efficient welding equipment as key drivers. The new BS EN ISO 14373-2024 standard adopted in Australia further optimizes the soft steel spot welding process and ensures that the welding process complies with environmental protection and safety requirements. This standard focuses on reducing carbon emissions and optimizing welding parameters for better energy efficiency. It applies to the welding of uncoated or coated mild steels.

Support for industrial policies and applications

The Australian government has invested Australian $22.7 billion as part of its Future Made in Australia initiative to promote green manufacturing technologies, including low-carbon metallurgy and clean energy applications. In the defence and infrastructure sectors, the government recently allocated Australian $17.3 million to help smes upgrade their welding equipment to improve productivity and sustainability.

Perspectives for the future

The carbon footprint of Australian manufacturing will be even smaller as intelligent welding technology and automated systems become widespread. Robotic welding systems reduce energy consumption by 50% while increasing production efficiency. Combined with government policy and business innovation, spot welding technology will continue to play an important role in Australia’s sustainable manufacturing strategy, helping the country meet its net zero emissions target by 2050.

As part of the global race for green industry, Australia’s advances in spot welding not only improve the competitiveness of local manufacturing, but also offer a solution from which global

low-carbon production can be borrowed.

Post time: Aug-01-2025