In the rapidly developing lithium battery manufacturing industry, choosing the right welding technology is crucial for ensuring production efficiency and product quality. As a leading company with over 20 years of experience in lithium battery welding equipment R&D, Styler understands that true optimization can only be achieved by matching the welding process with the specific battery type, production scale, and cost control.

Currently, there are two main welding technologies available for lithium battery module assembly lines: spot welding machines and laser welding machines. Each has its advantages and is suitable for different production needs.

Spot welding machines are well-suited for welding nickel busbar and cylindrical lithium batteries, known for their high efficiency and speed, making them suitable for mass production. For companies prioritizing output and stability, investing in a high-performance spot welding machine can significantly improve production line efficiency while ensuring consistent quality.

(Credit: pixabay Images)

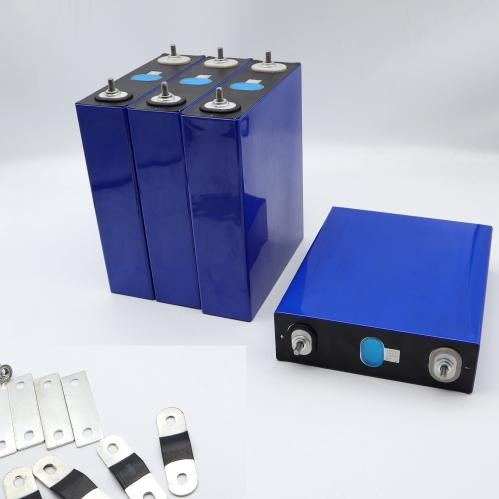

Laser welding machines offer higher precision and flexibility, capable of handling complex battery designs, and are more suitable for multi-variety production models. Laser welding produces fine and strong welds, making it favored by manufacturers seeking process innovation or producing special battery models.

(Credit: styler Images)

In practical selection, the welding process must comprehensively consider the specific battery specifications, expected output, and investment budget. For example, spot welding is often more cost-effective in mass production; while for high-end battery products with stringent process requirements, laser welding, although requiring a higher initial investment, provides indispensable precision and consistency.

Styler is committed to providing customers with customized solutions tailored to their production goals. Leveraging our extensive experience in lithium-ion battery welding, we help manufacturers make informed technology choices, thereby improving the efficiency and quality of their overall assembly lines.

Want to upgrade your technology? Let’s talk. Visiting our website http://www.styler.com.cn , just email us sales2@styler.com.cn and contact via +86 15975229945.

Post time: Dec-17-2025