With lithium batteries in high demand, manufacturers need welding methods that balance speed, cost, and quality. Spot welding and laser welding are the top choices—but which one is right for your production line?

Spot Welding: Fast, Reliable, and Cost-Effective

Spot welding has been a go-to method for lithium battery assembly, especially for nickel busbars and cylindrical cells. It works by sending a quick electric pulse to fuse metals, creating strong joints with minimal heat damage to surrounding areas.

(Credit: pixabay Images)

Why choose spot welding?

1)Proven for mass production-It’s fast, consistent, and cost-efficient, making it ideal for high-volume EV and consumer battery manufacturing.

2)Great for nickel-Works exceptionally well with nickel busbar, a common material in battery packs.

At Styler, we specialize in precision spot welding machines that ensure repeatable, high-quality welds—whether for small Li-ion cells or large EV battery modules.

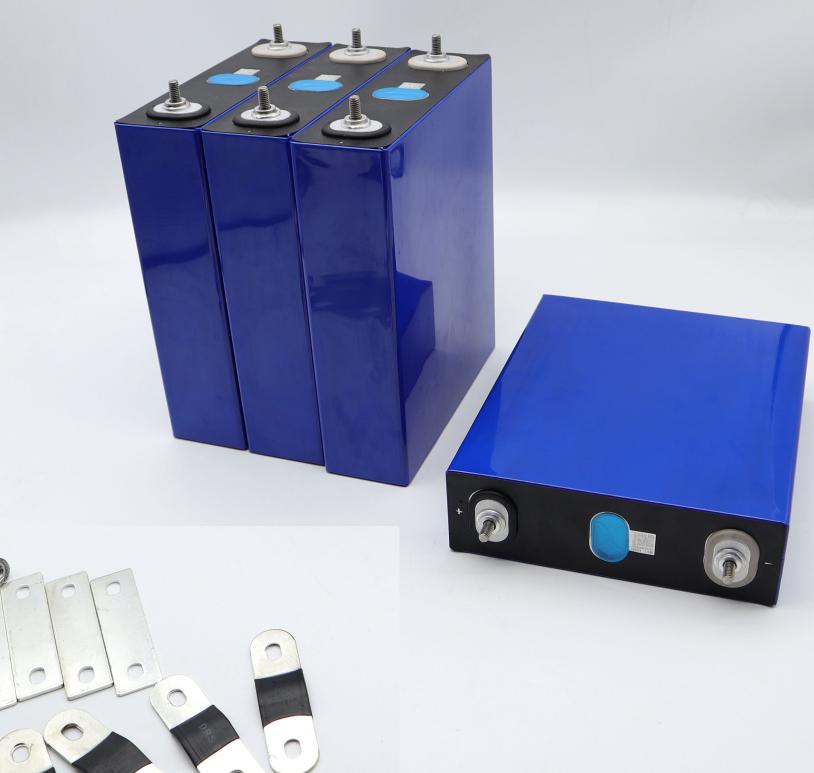

Laser Welding: High Precision for Complex Designs

Laser welding uses a focused beam to melt and join materials with extreme accuracy. It’s the preferred choice for prismatic and pouch cells, where tight tolerances and clean seams matter.

(Credit: styler Images)

When does laser welding make sense?

1)Aluminum welding-Unlike spot welding, lasers handle aluminum efficiently.

2)Applicable scenarios-Suitable for thin metal busbars, among which aluminum busbars are the most common.

Applicable cells-Prismatic batteries and pouch batteries are the most commonly used. Some cylindrical cells can also be laser welded. It mainly depends on the material of the cell shell and the positive and negative electrodes.

However, laser systems come with higher upfront costs and require more expertise to operate.

So which one makes sense for you?

1) Working with nickel-based cylindrical cells? Stick with spot welding – it’s cost-efficient and battle-tested.

2) Dealing with aluminum cases or pouch cells? Laser’s your best bet, no question.

Where we come in:

At Styler, we’ve specialized in spot welding solutions that tackle real production challenges:

1) When speed is non-negotiable

2) When budgets matter

3) When consistency can’t be compromised

Our machines are built for the grind of high-volume production, delivering reliable quality shift after shift.

Post time: Aug-06-2025