Products

IPV200 Resistance Welding Machine

Product Features

Primary constant current control, constant voltage control, mixed control, ensuring the diversity of welding. High control rate: 4KHz.

Up to 50 stored welding patterns memory, handling different workpiece.

Less welding spray for a clean and fine welding result.

High reliability and high efficiency.

Product Details

Parameter attribute

| MO DEL | IPV100 | IPV200 | IPV300 | IPV500 |

| ELEC TRICAL PARAMETERS | max curr:1500A | max curr:2500A | max curr:3500A | max curr:5000A |

| ELEC TRICAL PARAMETERS | no-load volt: 7 .2V | no-load volt:8.5V | no-load volt 9 | no-load volt:10V |

| input: 3 phase 340~420VAC 50/60Hz | ||||

| RATED CAPACITY OF TRANSFORMER | 3.5KVA | 5.5KVA | 8.5KVA | 15KVA |

| CONTROLS | primarily const curr, const . volt , mixed contro volt:00.0%~99 .9% | |||

| CONTROL ACCURACY | curr:200~1500A | curr:400~2500A | curr:400~3500A | curr:800~5000A |

| slow rising 1, slow rising 2:00~49ms | ||||

| welding time 1:00~99ms;welding time 2:000~299ms | ||||

| slow down time 1 ; slow down time 2:00~49ms | ||||

| detected peak curr value: 0-8000 | ||||

| TIME SETTING | pressure contact time: 0000~9999ms | |||

| welding pole cooling time: 000~999ms | ||||

| holding time after welding: 000~999ms | ||||

| COOLING METHOD | air | |||

| EX.SIZE | 215(W)X431( D)X274(H)mm | |||

| PACKING SIZE | 280(W)X530( D)X340(H)mm | |||

| GW | 17KG | 23KG | ||

Why Choose Us

-Do we support OEM or ODM?

-Will the original R&D manufacturing paint have a price advantage?

-Are you products high quality products?

-Do we have a good team?

-Does our product support global after-sales service ?

-Are our product certified?

every answer is "YES"

Popular Science Knowledge

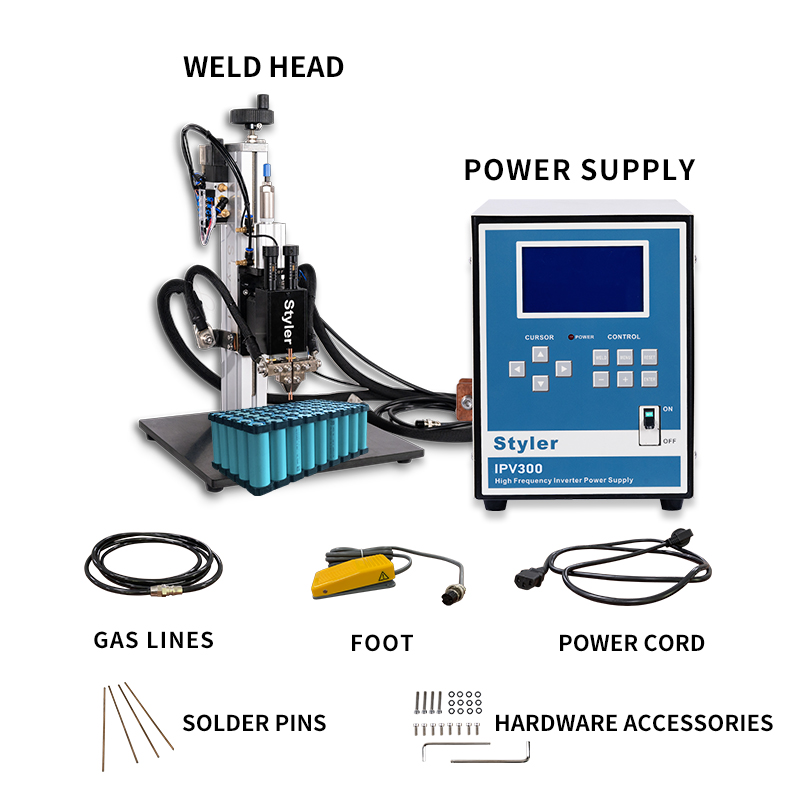

This pneumatic spot welding machine is mainly used for 18650 cylinder call pack welding, it can weld Nickel tab thickness from 0.02-0.2 mm with good welding effect.

The Pneumatic model is with smaller volume and weight, easy for international shipping.

Sinlge point needle can be used for Ni tab weld with Stainless steel case.

1. Microcomputer control, CNC current adjust.

2. High precision welding power.

3. Digital tube display, keyboard control, welding parameters flash storage.

4. Double pulse welding, make welding more firmly.

5. Small welding sparks, solder joint uniform appearance, the surface is clean.

6. Welding times can be set.

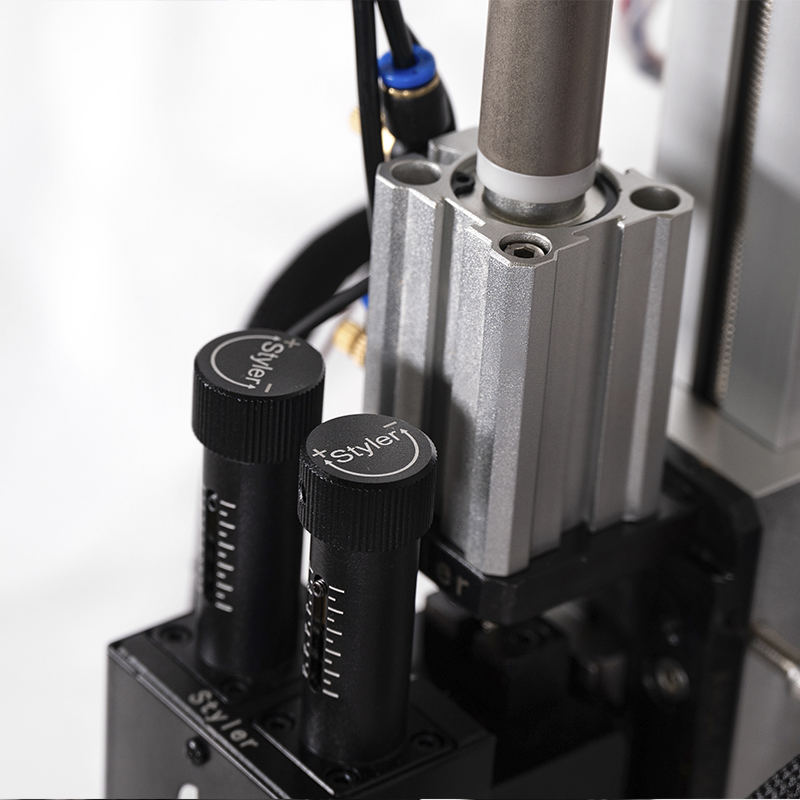

7. Can set preloading time, the holding time, time to rest, the welding speed can be adjusted.

8. Large power, stable and reliable.

9. Double needle pressure adjustable separately, Suitable for different thickness of Nickel strip.