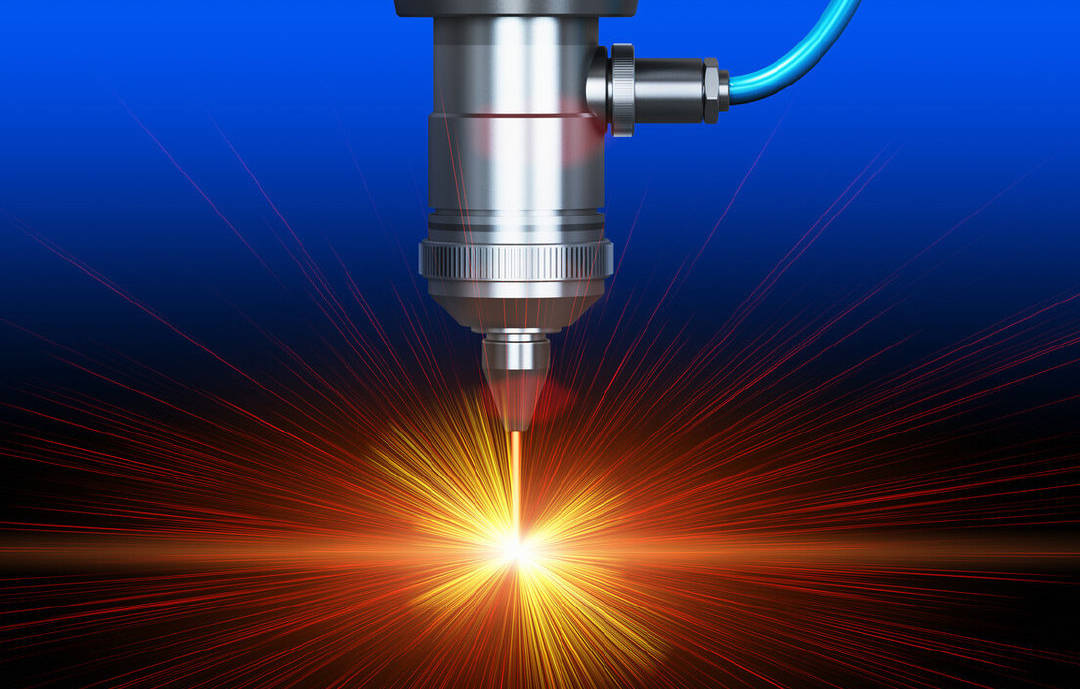

Laser marking machines are cutting-edge devices that utilize laser beams for engraving and marking purposes. Widely employed in industrial production, these machines can create intricate markings and engravings on diverse materials, such as metal, plastic, and glass. Renowned for their efficiency and precision, laser marking machines have become the preferred choice for enterprises and individuals alike.

The process of laser marking involves using laser beams for evaporation, oxidation, or color transfer to mark the object's surface. When compared to traditional engraving methods, laser marking offers several unique advantages.

Firstly, the laser marking process does not require direct contact with the object's surface, preventing any potential damage caused by mechanical engraving. Secondly, laser marking machines ensure greater precision and finer details in the marked text, patterns, barcodes, and graphics, eliminating any blurriness or fuzziness.

Moreover, laser marking machines boast user-friendly operation, stability, and durability, enabling them to withstand long periods of high-intensity work. Their applications span across various industries. For instance, in the field of electronic parts manufacturing, laser marking machines can engrave essential information on precision components for anti-counterfeiting and traceability purposes. In the pharmaceutical industry, they can mark drug packaging to ensure authenticity and expiration dates. In the jewelry-making industry, laser marking machines can engrave intricate patterns or letters on precious metals, adding unique cultural value to jewelry.

Additionally, laser marking machines play a pivotal role in automotive manufacturing, aerospace, toy production, and other industries by providing product identification and essential information.

There are diverse types of laser marking machines available, each catering to specific needs and material characteristics. Common models include fiber laser marking machines, carbon dioxide laser marking machines, and UV laser marking machines. Fiber laser machines are ideal for most metal materials due to their high efficiency and precise marking capabilities. Carbon dioxide laser machines are best suited for organic materials like wood and leather. UV laser machines, on the other hand, are suitable for transparent materials such as plastic and glass.

Beyond industrial production, laser marking machines hold significant potential in artistic creation and personalized customization. They enable the creation of personalized gifts, souvenirs, business cards, and other items, providing customers with unique products. In terms of artistic endeavors, laser marking machines can produce delicate and exquisite works of art, pushing the boundaries of creativity.

In conclusion, laser marking machines, with their efficiency and accuracy, have emerged as essential tools for modern industrial production and creative design. Their widespread application allows various industries to meet market demands more effectively, leading to improved production efficiency and product quality. The continued development of laser marking technology will undoubtedly fuel technological progress and societal advancement.

The information provided by Styler (“we,” “us” or “our”) on (the “Site”) is for general informational purposes only. All information on the Site is provided in good faith, however, we make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability or completeness of any information on the Site. UNDER NO CIRCUMSTANCE SHALL WE HAVE ANY LIABILITY TO YOU FOR ANY LOSS OR DAMAGE OF ANY KIND INCURRED AS A RESULT OF THE USE OF THE SITE OR RELIANCE ON ANY INFORMATION PROVIDED ON THE SITE. YOUR USE OF THE SITE AND YOUR RELIANCE ON ANY INFORMATION ON THE SITE IS SOLELY AT YOUR OWN RISK.

Post time: Jul-28-2023