Products

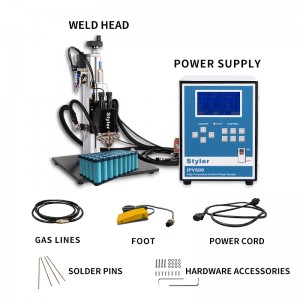

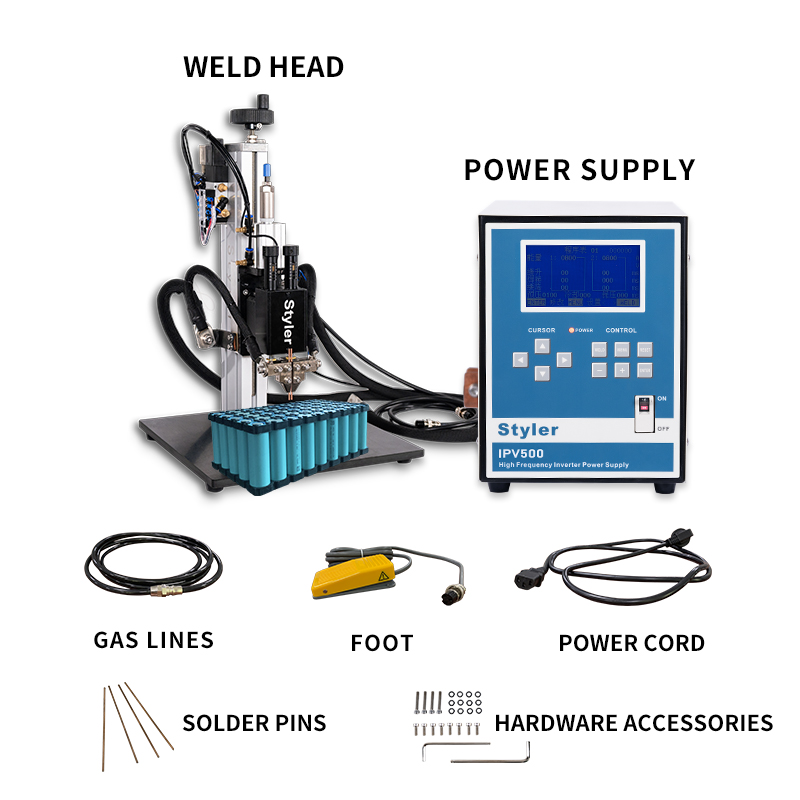

Styler 5000A spot soldering machine

Product Features

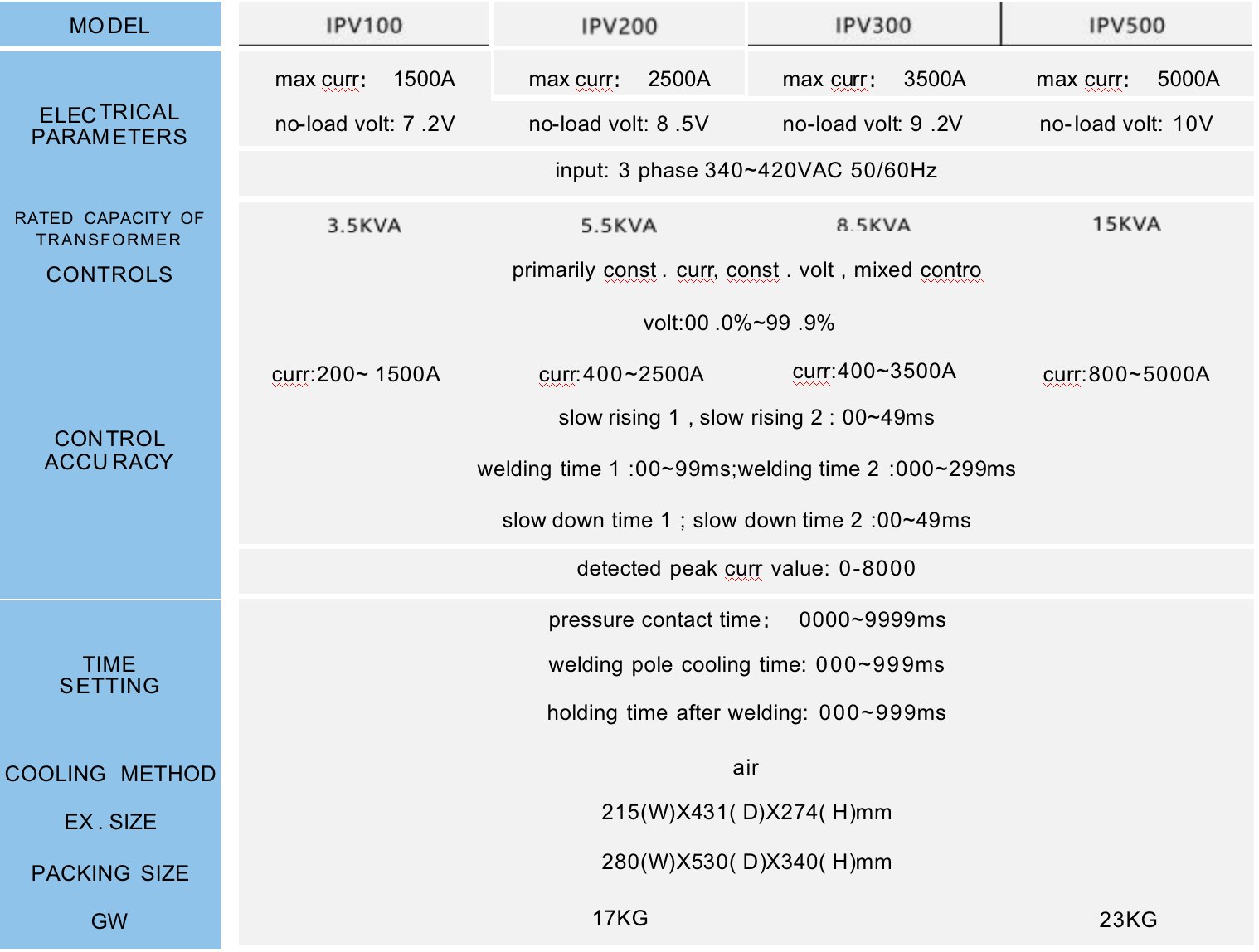

Primary constant current control, constant voltage control, mixed control, ensuring the diversity of welding. High control rate: 4KHz.

Up to 50 stored welding patterns memory, handling different workpiece.

Less welding spray for a clean and fine welding result.

High reliability and high efficiency.

Product Details

Parameter Attribute

Why Choose Us

1. We have been focusing on the field of precision resistance welding for 12 years, and we have rich industry cases.

2. We have core technology and strong R & D capabilities, and can develop personalized functions according to customer needs

3. We can provide you with professional welding scheme design.

4. Our products and services have a good reputation.

5. We can provide the cost-effective products directly from factory.

6. We have a complete range of product models.

7. We can provide you with professional pre-sales and after-sales consultation within 24 hours.

Our service

Pre-sales Service

1. Help customer analyze product project and provide professional welding solution.

2. Free sample test welding.

3. Skilled jig design services.

4. Provide shipping/delivery information checking service.

5. 24 hours feedback speed by email of others. 6. View our factory

After-Sales service

1.Training how to install and use the Equipment on line or by video technical support.

2.The engineer can provide welding process guidance and solve various technical problems in the use of equipment.

3.We provide 1year (12 months) quality warranty. During the warranty period, if there is any quality problem with the machine, we will replace you with new parts free of charge and send it to you by express on our freight. And provide the technical consultant for any time. If more terrible, we can send our engineers to your factory.