Products

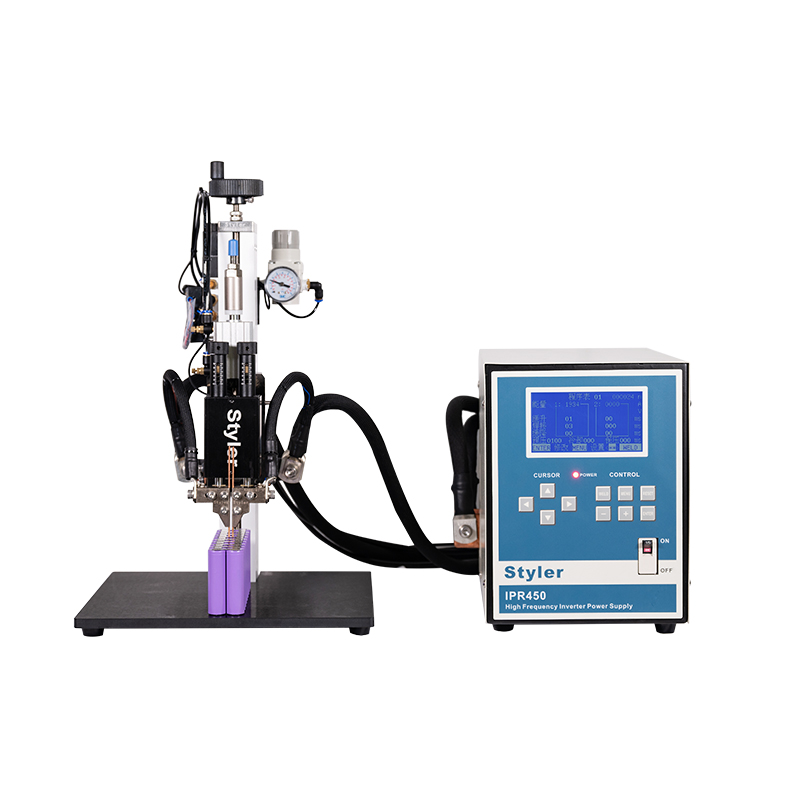

IPR450 Precision High-Frequency Inverter Resistance Welding Machine

Product Features

The primary constant current mode is adopted ,and the welding current rises quickly

High speed control speed of 4k Hz

Store 50 kinds of welding specifications ,corresponding to different welding workpieces .

Reduce welding spatter and achieve cleaner and more beautiful appearance

High reliability and high efficiency

Product Details

Parameter attribute

Optional accessories

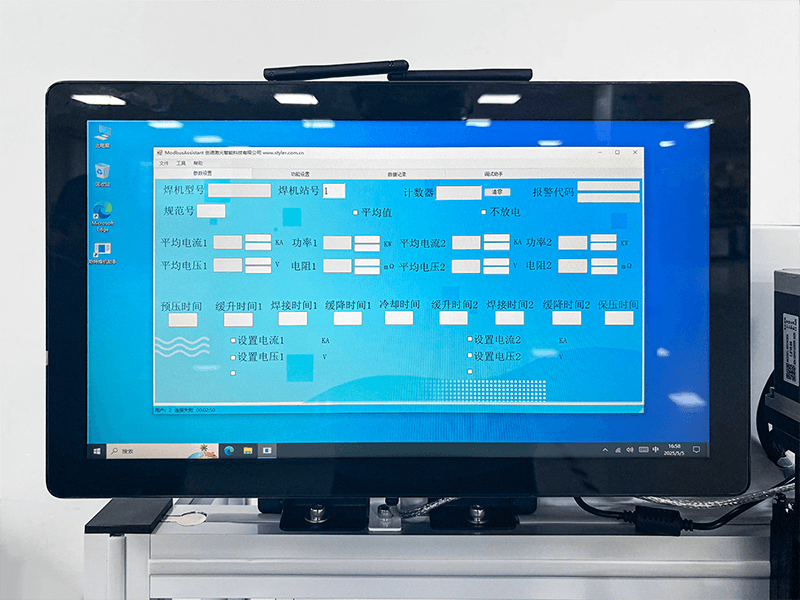

Computer (real-time monitoring of solder joints, data can be sent via RS485)

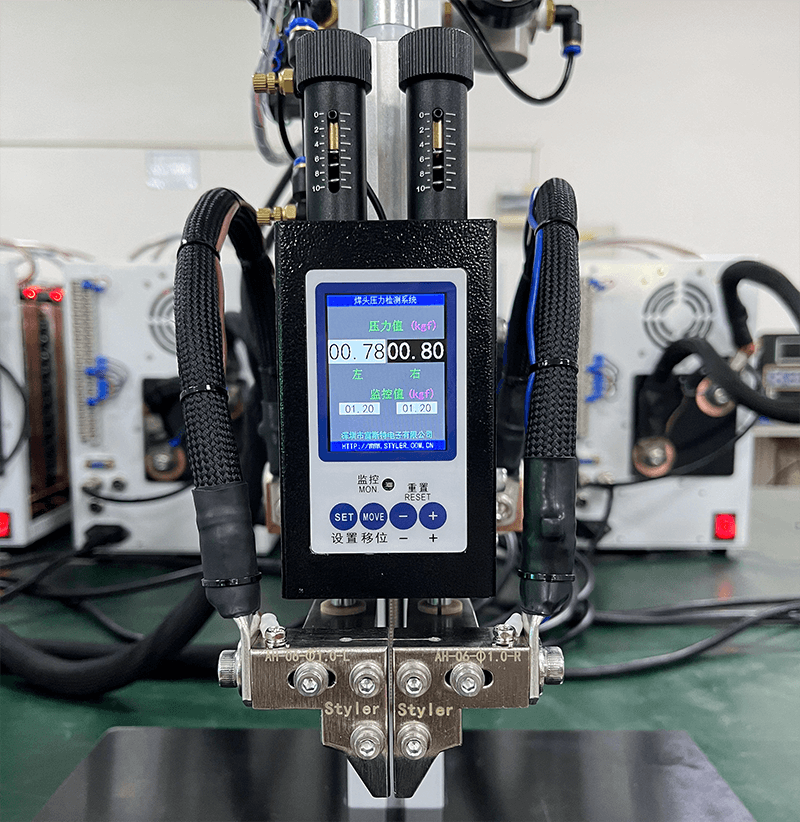

Add a pressure sensor to the welding head (the pressure of the clamps on both sides can be set to be consistent, and the pressure during welding can be monitored)

Popular Science Knowledge

Transistor spot welding machine welding current rises very fast, can complete the welding process in a short time, the welding heat affected zone is small, and the welding process has no spatter. It is most suitable for ultra-precision welding, such as thin wires, such as button battery connectors, Small contacts and metal foils of relays