Products

PR50 Battery Welder

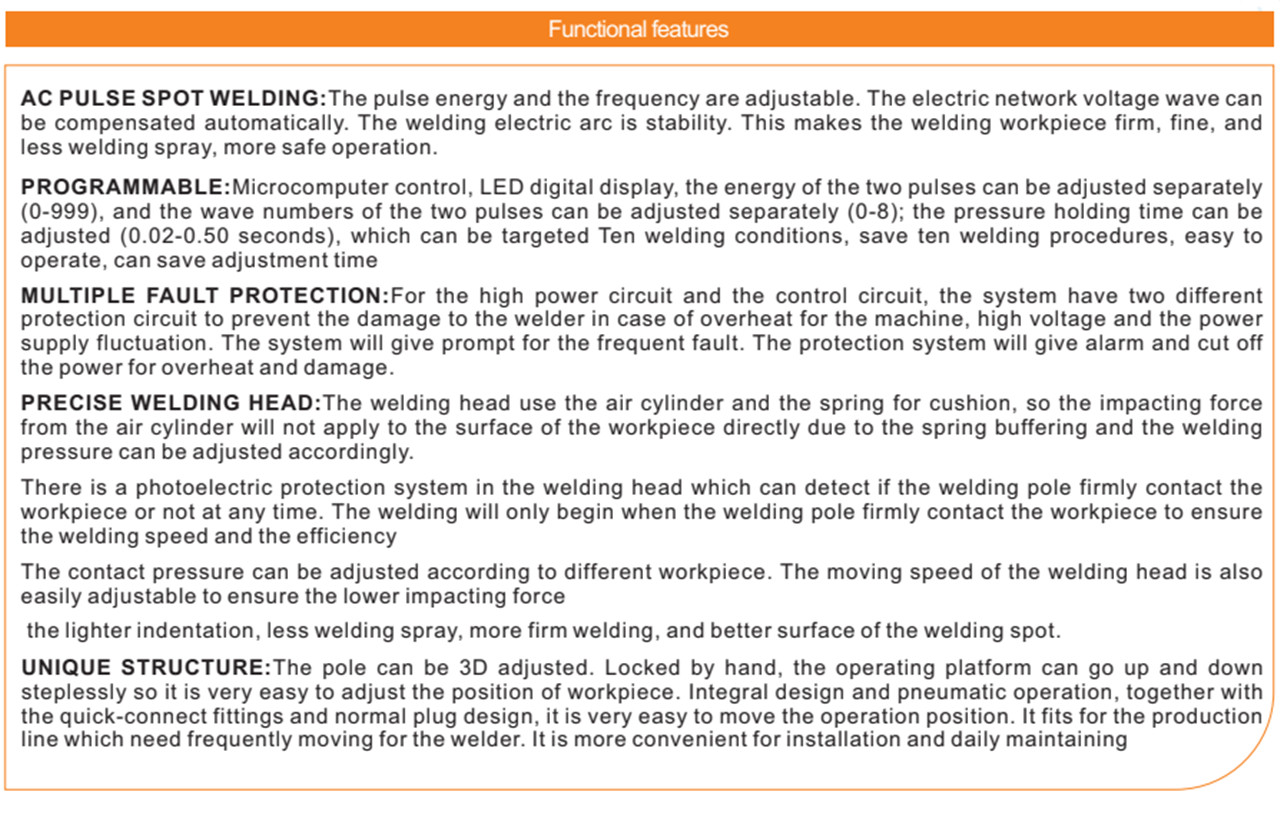

Equipment FEATURES

Microcomputer digital control, welding energy accurately adjustable.

Up to 10 stored welding patterns memory, handling different workpiece.

The cylind stroke can be adjusted(optional function).

Discharging time can be controlled accurately by the photoelectric system.

High reliability and high efficiency.

Welding static pressure and speed can be fine tuned.

Scope of application: combined welding of notebook batteries (18650 and other cylindrical lithium batteries); Welding of cell negative electrode, aluminum nickel composite belt and protective plate of lithium ion battery; Combination welding of Ni MH Ni Cd battery, etc. It is suitable for the welding of battery pole pieces with a thickness of less than 0.25mm and the occasions where the pressure and welding speed need to be accurately adjusted.

Product Details

Why Choose Us

Styler have a professional engineering and technical service team, provide lithium battery PACK automatic production line, lithium battery assembly technical guidance, and technical training.

We can provide you with a full line of equipment for battery pack production.

We can provide you with the most competitive price directly from the factory.

We can provide you with the most professional after-sales service 7*24 hours.

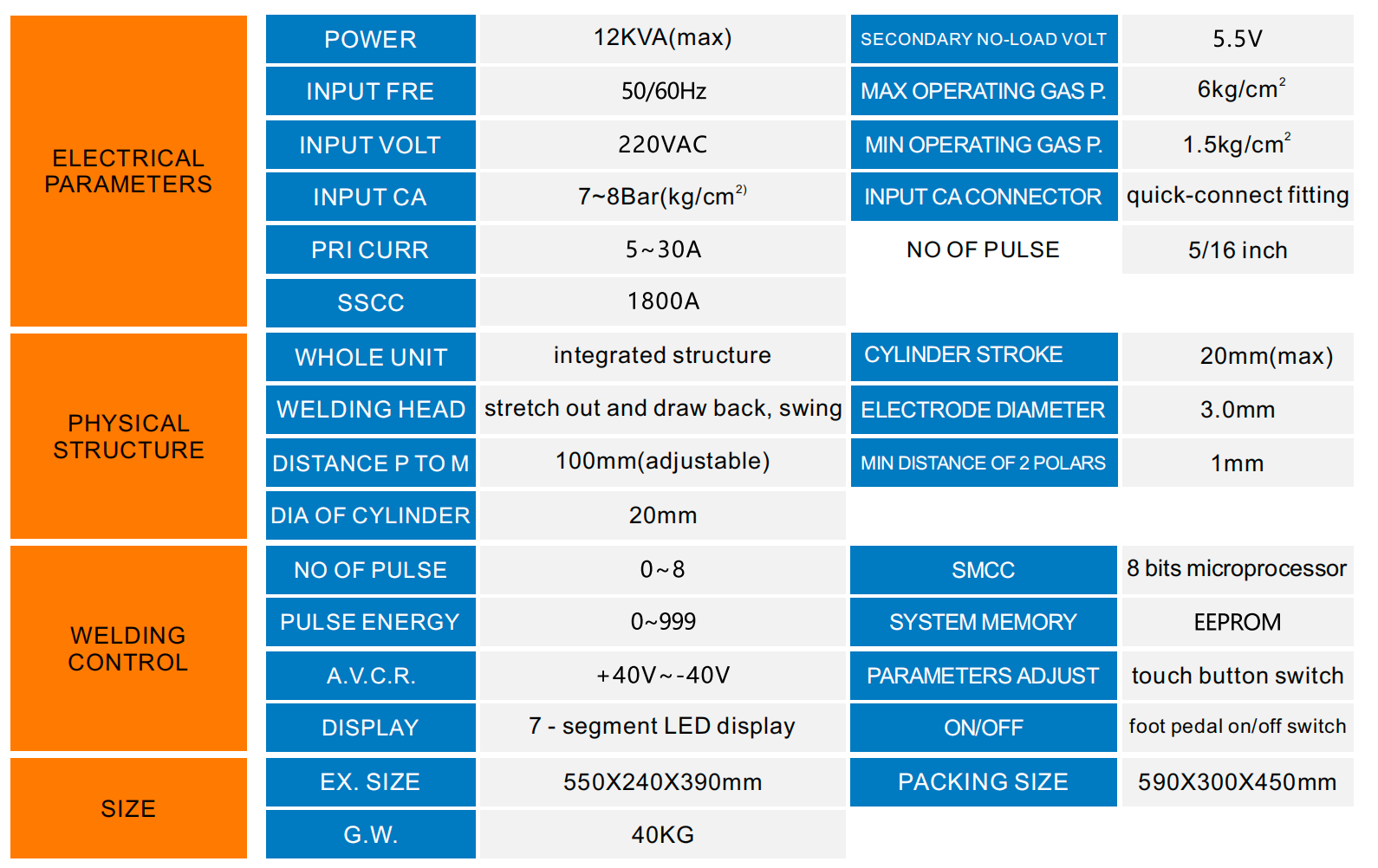

Parameter attribute

Popular Science Knowledge

It can weld various special materials, especially suitable for precision connection of stainless steel, copper, aluminum, nickel, titanium, magnesium, molybdenum, tantalum, niobium, silver, platinum, zirconium, uranium, beryllium, lead and their alloys. Applications include micromotor terminals and enamelled wires, plug-in components, batteries, optoelectronics, cables, piezoelectric crystals, sensitive components and sensors, capacitors and other electronic components, medical devices, all kinds of electronic components with small coils that need to be directly welded with enamelled wires, micro welding and other occasions with high welding requirements, and other spot welding equipment can not meet the welding process requirements.

We are based in Guangdong, China, start from 2010,sell to Domestic Market(50.00%),North America(15.00%),South America(5.00%),Eastern Europe(5.00%),Western Europe(5.00%),Southeast Asia(3.00%),Oceania(3.00%),Eastern Asia(3.00%),South Asia(3.00%),Mid East(2.00%),Central America(2.00%),Northern Europe(2.00%),Southern Europe(2.00%). There are total about 51-100 people in our office.

Always a pre-production sample before mass production; Always final Inspection before shipment;

Lithium Battery Assembly Automation Line,Battery Spot Welding Machine,Battery Sorting Machine,Battery Comprehensive Tester System,Battery Aging Cabinet

We have a strong technical R&D team and have been working in the lithium battery assembly and manufacturing industry for many years with rich experience. The company now has a variety of specifications and models of machinery and equipment, various series

Accepted Delivery Terms: FOB,EXW; Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF; Accepted Payment Type: T/T,L/C,D/P D/A,PayPal; Language Spoken:English,Chinese