Products

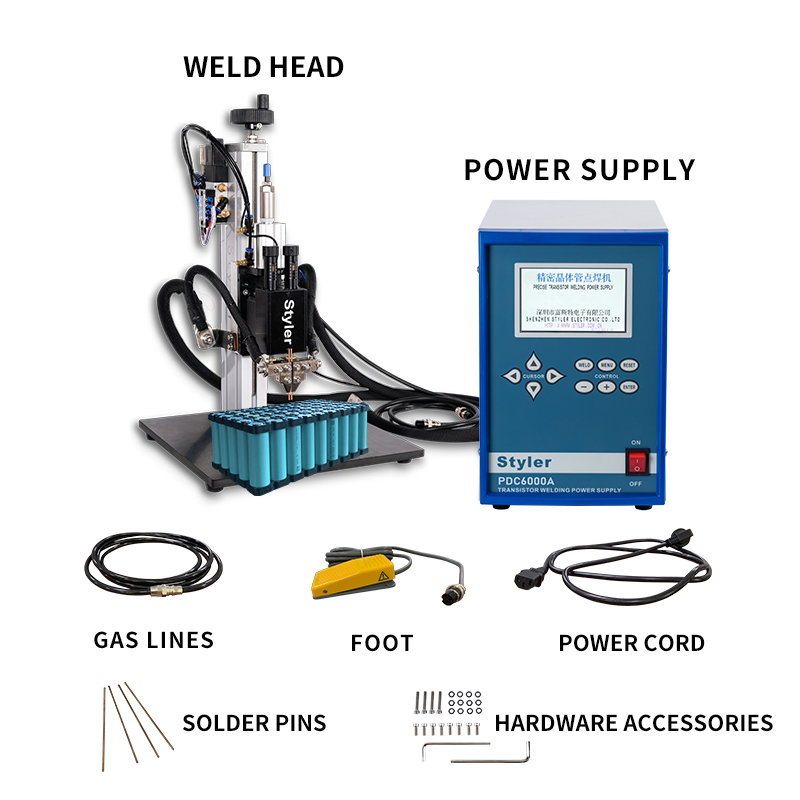

PDC6000A Spot Welding Machine

Product Features

Primary constant current , constant voltage and hybrid control mode are adopted to ensure the diversification of welding process.

Large LCD screen, which can display welding current, power and voltage between electrodes, as well as contact resistance.

Built-in detection function: before the formal power-on, a detection current can be used to confirm the presence of the workpiece and the status of the workpiece.

A power source and two welding heads can work at the same time.

The actual welding parameters can be output through the RS-485 serial port.

Can switch 32 groups of energy arbitrarily through external ports.

Complete input and output signals, which can be used in conjunction with a high degree of automation. Can remotely modify and call parameters through Modbus RTU protocol.

Product Application

It can weld various special materials, especially suitable for precision connection of stainless steel, copper, aluminum, nickel, titanium, magnesium, molybdenum, tantalum, niobium, silver, platinum, zirconium, uranium, beryllium, lead and their alloys. Applications include micromotor terminals and enamelled wires, plug-in components, batteries, optoelectronics, cables, piezoelectric crystals, sensitive components and sensors, capacitors and other electronic components, medical devices, all kinds of electronic components with small coils that need to be directly welded with enamelled wires, micro welding and other occasions with high welding requirements, and other spot welding equipment can not meet the welding process requirements.

Product Details

Parameter attribute

|

Device parameters |

|||||

|

MODEL |

PDC10000A |

PDC6000A |

PDC4000A |

||

|

MAX CURR |

10000A |

6000A |

2000A |

||

|

MAX POWER |

800W |

500W |

300W |

||

|

TYPE |

STD |

STD |

STD |

||

|

MAX VOLT |

30V |

||||

|

INPUT |

single phase 100~ 120VAC or single phase200~240VAC 50/60Hz |

||||

|

CONTROLS |

1 .const , curr;2 .const , volt;3 .const . curr and volt combination;4 .const power;5 .const .curr and power combination |

||||

|

TIME |

pressure contact time: 0000~2999ms resistance pre-detection welding time: 0 .00~ 1 .00ms pre-detection time: 2ms(fixed) rising time: 0 .00~20 .0ms resistance pre-detection 1 ,2 welding time: 0 .00~99 .9ms slow down time: 0 .00~20 .0ms cooling time: 0 .00~9 .99ms holding time: 000~999ms |

||||

|

SETTINGS

|

0.00~9.99KA |

0.00~6.00KA |

0.00~4.00KA |

||

|

0.00~9.99v |

|||||

|

0.00~99.9KW |

|||||

|

0.00~9.99KA |

|||||

|

0.00~9.99V |

|||||

|

0.00~99.9KW |

|||||

|

00.0~9.99MΩ |

|||||

|

CURR RG |

205(W)×310(H)×446(D) |

205(W)×310(H)×446(D) |

|||

|

VOLT RG |

24KG |

18KG |

16KG |

||

Why choose us

1. We have been focusing on the field of precision resistance welding for 12 years, and we have rich industry cases.

2. We have core technology and strong R & D capabilities, and can develop personalized functions according to customer needs

3. We can provide you with professional welding scheme design.

4. Our products and services have a good reputation.

5. We can provide the cost-effective products directly from factory.

6. We have a complete range of product models.

7. We can provide you with professional pre-sales and after-sales consultation within 24 hours.